Table of Contents

Cost-Effective Solutions for LDY Metallurgical Electric Single Beam Cranes

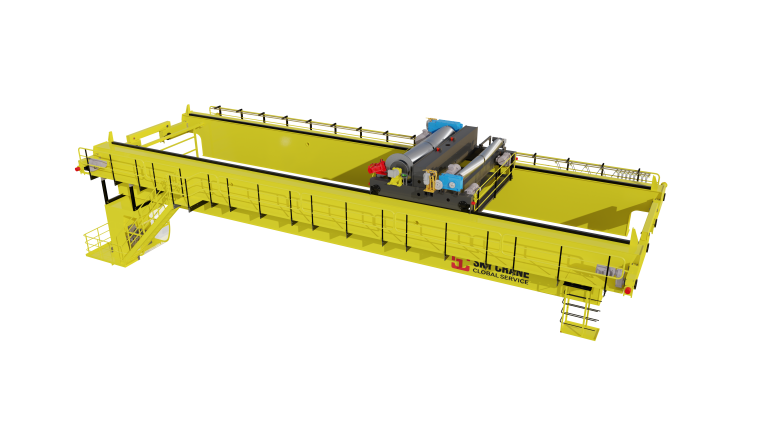

In the realm of industrial lifting solutions, LDY metallurgical electric single beam cranes have emerged as a popular choice for various applications, particularly in metallurgical and manufacturing environments. These cranes are designed to provide efficient and reliable lifting capabilities, making them indispensable in settings where heavy materials need to be moved with precision. However, one of the most significant considerations for businesses looking to invest in such equipment is cost-effectiveness. Fortunately, LDY cranes offer a range of options that cater to budget-conscious buyers without compromising on quality or performance.

When exploring cost-effective solutions for LDY metallurgical electric single beam cranes, it is essential to recognize the advantages of custom orders. Customization allows businesses to tailor the crane specifications to their unique operational needs, which can lead to significant savings in the long run. By selecting only the features that are necessary for their specific applications, companies can avoid the expense of purchasing a more complex system that includes unnecessary capabilities. This targeted approach not only reduces initial investment costs but also minimizes maintenance and operational expenses over time.

Moreover, the competitive pricing of LDY cranes makes them an attractive option for businesses seeking affordable lifting solutions. The manufacturers of these cranes often provide various pricing tiers based on the specifications and features selected. This flexibility enables companies to find a model that fits their budget while still meeting their operational requirements. Additionally, the availability of bulk purchasing options can further enhance cost savings, as many suppliers offer discounts for larger orders. This is particularly beneficial for businesses that require multiple cranes for different locations or projects.

In addition to the initial purchase price, it is crucial to consider the long-term operational costs associated with LDY metallurgical electric single beam cranes. These cranes are designed with energy efficiency in mind, which can lead to substantial savings on electricity bills over time. By investing in a crane that operates efficiently, businesses can reduce their overall energy consumption, contributing to lower operational costs and a smaller carbon footprint. Furthermore, LDY cranes are built with durable materials and advanced technology, which translates to lower maintenance costs and extended service life. This durability ensures that companies can rely on their cranes for years to come, making them a wise investment.

| Number | Article Name |

| 1 | LX electric suspension crane |

| 2 | MH rack crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Another aspect to consider is the availability of after-sales support and service. Many manufacturers of LDY cranes offer comprehensive support packages that include installation, training, and maintenance services. This support not only enhances the operational efficiency of the cranes but also provides peace of mind for businesses. Knowing that expert assistance is readily available can alleviate concerns about potential downtime or operational issues, further solidifying the cost-effectiveness of the investment.

In conclusion, LDY metallurgical electric single beam cranes present a compelling option for businesses seeking cost-effective lifting solutions. Through customization, competitive pricing, energy efficiency, and robust after-sales support, these cranes offer a balanced approach to meeting industrial lifting needs without straining budgets. As companies continue to seek ways to optimize their operations while managing costs, LDY cranes stand out as a reliable and economical choice in the market. By carefully considering their options and leveraging the benefits of LDY cranes, businesses can enhance their productivity and efficiency while maintaining financial prudence.

Custom Orders: Tailoring LDY Metallurgical Electric Single Beam Cranes to Your Needs

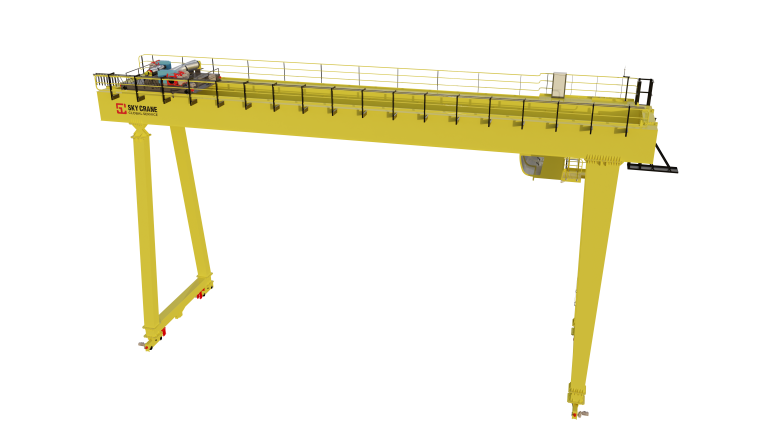

In the realm of industrial lifting solutions, the LDY Metallurgical Electric Single Beam Crane stands out as a versatile and efficient option for various applications. One of the most significant advantages of this crane is the ability to customize it according to specific operational requirements. Custom orders allow businesses to tailor the crane’s features, ensuring that it meets their unique needs while maintaining cost-effectiveness. This flexibility is particularly beneficial in industries such as metallurgy, where precise lifting capabilities and durability are paramount.

When considering a custom order for an LDY Metallurgical Electric Single Beam Crane, it is essential to evaluate the specific requirements of your operation. Factors such as load capacity, span length, lifting height, and operational environment play a crucial role in determining the ideal configuration. By engaging with manufacturers or suppliers, businesses can discuss their operational challenges and expectations, leading to a tailored solution that enhances productivity and safety.

Moreover, the customization process often includes selecting the appropriate materials and components that align with the operational demands. For instance, in metallurgical applications, cranes may need to withstand high temperatures and corrosive environments. Therefore, opting for specialized materials that offer enhanced resistance to wear and tear can significantly extend the lifespan of the equipment. This consideration not only ensures reliability but also contributes to lower maintenance costs over time.

In addition to material selection, businesses can also customize the crane’s control systems. Advanced control technologies, such as remote operation and automated features, can be integrated into the design. These enhancements not only improve operational efficiency but also enhance safety by minimizing the need for personnel to be in close proximity to heavy loads. As industries increasingly prioritize safety and efficiency, the ability to customize control systems becomes a vital aspect of the crane’s design.

Furthermore, the aesthetic aspects of the crane can also be tailored to meet branding or operational preferences. While functionality is paramount, the visual appeal of the equipment can contribute to a professional image within the workplace. Custom paint colors or branding elements can be incorporated into the design, allowing businesses to maintain a cohesive look across their operations.

Cost considerations are also a significant factor when placing a custom order for an LDY Metallurgical Electric Single Beam Crane. While customization may initially seem more expensive, it is essential to view it as an investment in long-term efficiency and productivity. By ensuring that the crane is perfectly suited to the specific needs of the operation, businesses can avoid the pitfalls of using generic equipment that may not perform optimally. This tailored approach can lead to significant savings in operational costs, reduced downtime, and improved overall performance.

In conclusion, the option for custom orders of LDY Metallurgical Electric Single Beam Cranes presents a valuable opportunity for businesses to enhance their operational capabilities. By carefully considering the specific requirements of their operations, selecting appropriate materials and control systems, and even incorporating branding elements, companies can create a lifting solution that is not only efficient but also cost-effective. Ultimately, investing in a customized crane can lead to improved productivity, enhanced safety, and a stronger competitive edge in the market.