Table of Contents

Benefits of Customized Manual Single Beam Cranes

Manual single beam cranes are essential equipment in various industries for lifting and moving heavy loads. These cranes are versatile and can be customized to meet specific requirements, making them a popular choice for many businesses. In this article, we will explore the benefits of customized manual single beam cranes and how suppliers can tailor these cranes to suit individual needs.

| Serial Number | Article Name |

| 1 | European electric single beam |

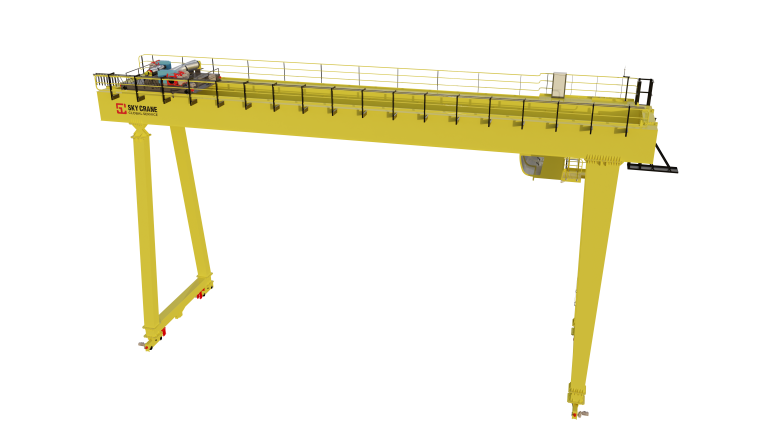

| 2 | Universal gantry crane |

| 3 | European-style crane |

| 4 | Harbour crane |

One of the primary advantages of customized manual single beam cranes is their ability to meet specific lifting requirements. Every industry has unique needs when it comes to lifting and moving heavy loads, and a one-size-fits-all approach may not always be suitable. By customizing a manual single beam crane, businesses can ensure that it is designed to handle the specific weight, size, and dimensions of the loads they need to lift.

Customized manual single beam cranes also offer increased efficiency and productivity. By tailoring the crane to the exact requirements of the job, businesses can streamline their lifting operations and reduce downtime. This can result in cost savings and improved workflow, ultimately leading to increased profitability.

Furthermore, customized manual single beam cranes can enhance safety in the workplace. By designing the crane to meet specific safety standards and requirements, businesses can minimize the risk of accidents and injuries. This is particularly important in industries where heavy lifting is a common task, as even a small mistake can have serious consequences.

Suppliers play a crucial role in the customization process of manual single beam cranes. They work closely with businesses to understand their needs and requirements, and then design and manufacture a crane that meets those specifications. Suppliers have the expertise and experience to create customized solutions that are efficient, safe, and reliable.

When choosing a supplier for a customized manual single beam crane, businesses should look for a company that has a proven track record of delivering high-quality products. It is essential to work with a supplier who understands the industry and can provide expert advice on the best crane design for the job. Additionally, businesses should consider factors such as cost, lead time, and after-sales support when selecting a supplier.

Customized manual single beam cranes can be designed to fit a wide range of applications. Whether businesses need a crane for a warehouse, construction site, or manufacturing facility, suppliers can tailor the crane to meet the specific requirements of the job. This flexibility makes customized manual single beam cranes a versatile and cost-effective solution for businesses of all sizes.

In conclusion, customized manual single beam cranes offer a range of benefits for businesses looking to improve their lifting operations. By working with a reputable supplier, businesses can design a crane that meets their specific requirements, enhances efficiency and productivity, and improves safety in the workplace. With the right supplier, businesses can enjoy the advantages of a customized manual single beam crane that is tailored to their needs.

Factors to Consider When Choosing a Supplier for Customized Manual Single Beam Cranes

When it comes to choosing a supplier for customized manual single beam cranes, there are several factors that need to be taken into consideration. These factors can greatly impact the quality, cost, and overall success of the project. In this article, we will discuss some of the key factors that should be considered when selecting a supplier for customized manual single beam cranes.

One of the most important factors to consider when choosing a supplier for customized manual single beam cranes is the supplier’s experience and expertise in the industry. It is essential to work with a supplier who has a proven track record of delivering high-quality products and services. A supplier with years of experience in designing and manufacturing manual single beam cranes will be able to provide valuable insights and recommendations to ensure that the final product meets your specific requirements.

Another important factor to consider is the supplier’s reputation in the industry. It is crucial to work with a supplier who has a solid reputation for delivering on their promises and providing excellent customer service. A supplier with a good reputation will be more likely to deliver a high-quality product on time and within budget. Additionally, a supplier with a strong reputation will be more likely to stand behind their products and provide support and assistance if any issues arise.

Cost is also a significant factor to consider when choosing a supplier for customized manual single beam cranes. It is essential to work with a supplier who can provide a competitive price without compromising on quality. While cost is important, it is crucial to remember that the cheapest option is not always the best option. It is essential to consider the overall value that the supplier can provide, including factors such as quality, reliability, and customer service.

Communication is another critical factor to consider when selecting a supplier for customized manual single beam cranes. Effective communication is essential to ensure that the supplier understands your specific requirements and can deliver a product that meets your needs. It is essential to work with a supplier who is responsive, transparent, and proactive in their communication. A supplier who communicates effectively will be able to provide updates on the project’s progress, address any concerns or issues promptly, and ensure that the final product meets your expectations.

Finally, it is essential to consider the supplier’s ability to customize manual single beam cranes to meet your specific requirements. A supplier who can provide customized solutions will be able to design and manufacture a product that meets your unique needs and specifications. It is essential to work with a supplier who has the expertise and capabilities to customize manual single beam cranes to your exact requirements, whether it be size, capacity, or functionality.

In conclusion, there are several factors to consider when choosing a supplier for customized manual single beam cranes. By considering factors such as experience, reputation, cost, communication, and customization capabilities, you can select a supplier who can deliver a high-quality product that meets your specific requirements. Working with the right supplier can make all the difference in the success of your project and ensure that you receive a manual single beam crane that meets your needs and exceeds your expectations.

Case Studies of Successful Implementations of Customized Manual Single Beam Cranes

Manual single beam cranes are a versatile and cost-effective solution for lifting and moving heavy loads in various industrial settings. These cranes are designed to be operated manually, making them ideal for applications where power sources may be limited or where precise control is required. One of the key advantages of manual single beam cranes is their ability to be customized to meet specific requirements, making them a popular choice for many businesses.

In this article, we will explore some case studies of successful implementations of customized manual single beam cranes by suppliers. These case studies will highlight the benefits of customization and how it can help businesses improve efficiency and safety in their operations.

One such case study involves a manufacturing company that needed a manual single beam crane with a longer reach to lift and move heavy materials within their facility. The supplier worked closely with the company to understand their specific requirements and designed a crane that met their needs. By customizing the crane with a longer beam and higher lifting capacity, the company was able to improve their productivity and reduce the risk of accidents.

Another case study involves a construction company that required a manual single beam crane with a rotating hook to lift and position materials in tight spaces. The supplier developed a crane with a rotating hook attachment that allowed the company to maneuver materials with precision and ease. This customization not only improved the company’s efficiency but also enhanced safety by reducing the risk of accidents during lifting operations.

Customization of manual single beam cranes can also help businesses optimize their workflow and maximize space utilization. A logistics company, for example, needed a crane that could be easily maneuvered in narrow aisles to lift and transport heavy pallets. The supplier designed a compact crane with a smaller footprint and improved maneuverability, allowing the company to streamline their operations and increase storage capacity.

In addition to improving efficiency and safety, customized manual single beam cranes can also help businesses reduce maintenance costs and downtime. A mining company, for instance, required a crane that could withstand harsh environmental conditions and heavy usage. The supplier customized the crane with durable materials and enhanced safety features, resulting in reduced maintenance requirements and increased reliability.

Overall, these case studies demonstrate the importance of customization in maximizing the benefits of manual single beam cranes. By working closely with suppliers to design cranes that meet their specific needs, businesses can improve efficiency, safety, and productivity in their operations. Whether it’s extending the reach, adding rotating hooks, or optimizing space utilization, customization can help businesses achieve their goals and stay competitive in today’s fast-paced industrial environment.